UJ/UQJ Products & Services

Our qualification services provide a design and qualification against international standards, ensuring that your subsea…

SubConnect showcased its unique ability to deliver comprehensive 360° project completion, from design, testing and qualification to the production of jointing kits. SubConnect was also able to help the client complete the project by providing expert Jointers and equipment which were deployed internationally via our sister company, Global Marine. Ensuring the successful execution of the client’s projects from design through to construction, testing, manufacturing, delivery, jointing, and preparation for cable laying.

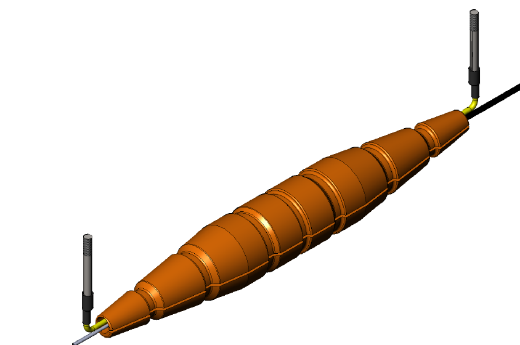

Collaborating with a long-term client, SubConnect’s team delivered a bespoke design that built on our long experience and knowledge incorporating custom features tailored to the client’s specific needs.

The team successfully deployed all required kits to multiple international locations for the cable manufacturer, where they were used across various cable systems.

From the initial design, kitting and installation the client has returned multiple times, some for repeat orders of kits and installation, but also design tweaks for cable variants.

As mentioned above, within this comprehensive 360° project, SubConnect not only leveraged the expertise and years of experience of the design team but also utilised its well-established testing facility to test these samples, including but not limited to:

All tests where conducted to the industry acknowledged ITU-T G976 standard in our UKAS accredited testing laboratory No 9277 (ISO/IEC 17025).

If you would like to find out more about this project or, if you have an upcoming project that could benefit from our expertise and services, including cable joint or subsea housing design, testing, qualification, or cable jointer hire, we’d love to talk to you.

Please contact us and we will get in touch you shortly

SubConnect has built a strong foundation of expertise, skills, pioneering technology, equipment, and assets. We have an established reputation for quality, expertise, and reliability.